:Sampling Technique:

Sample is a relatively small fraction which is selected to represent a population.

Two important reason for only testing sample are the time required per test and the destractive nature of many of test.

Exp: Bale Weight = 500lb

Testing Sample = 20mg

Bale Weight in mg = 500 x 453.6 x 1000 mg (For Accurate Result Use 453.56)

= 22,68,00,000 mg

Factor affecting sampling:

1. The form of the material.

2. Amount of the material available.

3. Nature of the test.

4. Type of the testing instrument.

5. Information required.

6. Degree of accuracy required.

Method of the Sampling:

1.Squaring Technique:

i.The sliver is opened out into a web and placed on a black velvet pad. The end of the sliver is then squared off.

ii. A glass plate is placed over the fibre and a small fringe is left projecting beyond the edge of the plate.

iii. All the protruding fibres are removed and discarded.

iv. The plate is moved back a little and a second fringe is removed.

v. Apparently the extent bias has been avoided since all the end of the fibres have terminated in a given volume.

vi. It is necessary to respect the operation until the final position of the plate edge was at least a distance equal to the length of the longest fibre present from its original position.

{It is necessary because,whenever a strand is broken their is a bias of fibres at each broken fringe.}

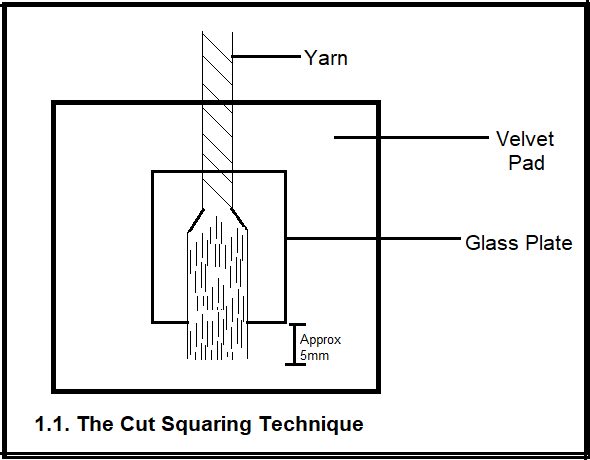

2. The Cut Squaring Method : This method is used when fibre in parallel order in form of yarn,roving and sliver.

i. The twisted form of material are first untwisted by hand.

ii. Then opened out a little, and laid parallel on a black velvet pad.

iii. A glass plate place over the fibres. The fringe is cut about 5mm from the edge of the plate. And removed by forceps and discarded.

iv. And the glass plate is move back about 1mm and repeat above process.

v. Finally, after a third movement of the glass plate, the fringe is removed and used as a sample.

Figure: 1.1 Cut Square Technique

3. Zoning Technique : This method is used for raw cotton, wool, and other loose fibre where the properties of fibre are vary at place to place.

i. From the bulk, a sample of about 2 oz is prepared by selecting about eighty large tufts chosen, so for as is possible over the bulk.

ii. Divide this sample into 4 parts.

iii. Take 16 small tufts at random from each parts, which size approx 20mg.

iv. Each tuft divide four times,and discard alternately with right and left hands and turning the tuft through a right angle between successive parts having sixteen wisps. this wisps are produce from each quarter sample.

v. Combine each set of wisps into a tufts.

vi. Mix Each tuft by using doubling and drawing by fingure.

vii. Divide each tufts into 4 parts.

viii. Obtain a new tuft from combining a 1/4 parts from each tufts.

ix. Mix each new tuft again by doubling and drawing.

x. Obtain a new tuft from combining a 1/4 parts from each tufts. And this is the final sample.

Figure: 1.2 - Zoning Technique

4. Length Extent And Bias Sampling Technique : The extent of a fibre in a strand is the distance parallel to the strand axis through which is extends.

The change of a fibre being selected from a strand and included in sample. The sample is proportional to its extent, and unless special sampling technique are used the sample will "extends biased".

The longer fibre will have more extent, because of this, a badly selected sample will have a bias toward the longer fibre.

i. A representation of a idealised sliver composed of 6,8 and 10 unit fibres are parallel to the sliver axis.

ii. Suppose we select for our sample all the fibre which cross the line A-A.

iii. The sample would consists of six fibres 6 unit long, eight fibre 8 unit long and ten fibre 10 unit long.

iv. Sample chosen in this way are therefore extend or length biased.

v. To obtain an unbiased sample only those fibre whose ends/min in a given volume should be selected.

vi. In figure 1.3, that all fibre which protrude part AA are combined away and discarded. Let AA moved back to the BB.

vii. The fibre now protruding part BB are those whose ends terminate in the volume AA/BB.

viii. If these fibre are combined away and classified into length group, it will seen thatt there are nine fibre in each of the 6,8 and 10 unit length group.

ix. This sample is unbiased sample and sampling complete.

Figure: 1.3- Lenth Extend And Length Bias Method

0 Comments